ZBHG series pump control panel is the company development of a new generation of energy-saving water supply products.

Its core is the AC frequency inverter technology and the microcomputer control technology. Use closed-loop control system. The control panel can automatically adjust the pump speed and the number of units running, so that the pressure of the water supply network to maintain the required pressure and flow, so as to improve the quality of water supply and high efficient energy saving purposes. The control cabinet can replace the high water-level tank, water tower and other facilities and valve adjustment and other measures . to improve the automation of water supply and drinking water quality, to prevent secondary pollution, is an ideal modern pump products.

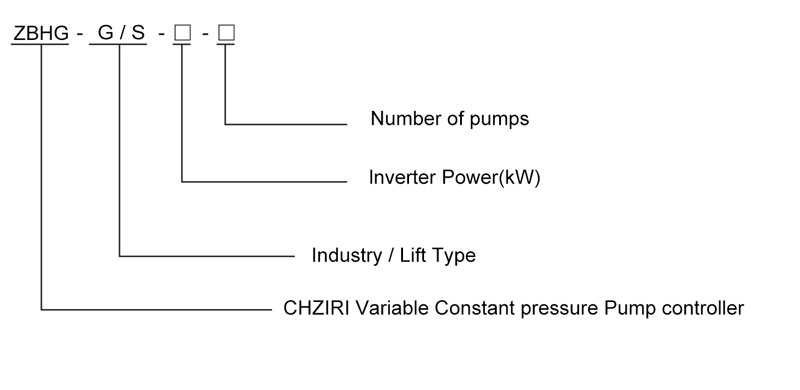

Demonstration of the Model

Product Characteristics

- 3 units main pumps + one unit small pump, Multi-speed control mode can be selected .

- Flexible increase 、decrease pump control logic.

- Flexible sleep pump control function.

- Regular rotation control, can effectively prevent the rust of the pump.

- Up to 8 periods of pressure control, and each period.

- Can be set to any arbitrary pressure setting control and realize time switch function.

- Pipe network pressure monitoring, alarm; pump grounding, loss phase and so on perfect protection.

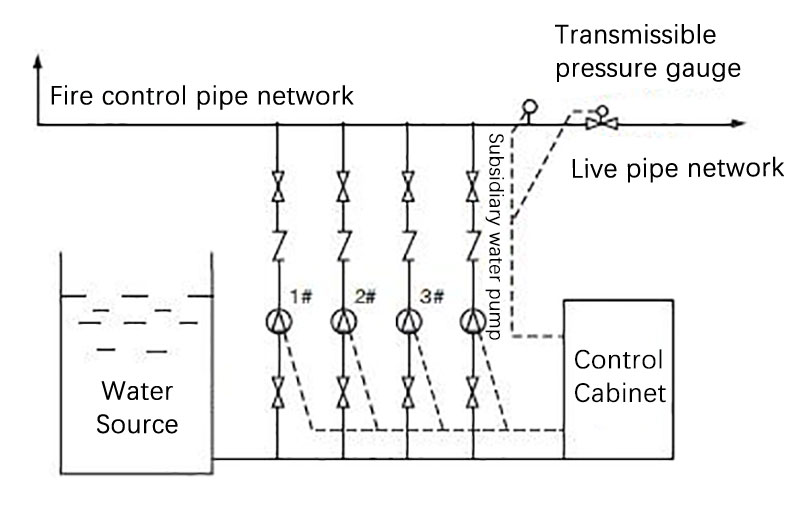

When water supply automatic control system is working , Through the high sensitivity pressure transducer which is installed in the water supply network. the equipment detect the water supply network's pressure change when water level changes.

Continuously transmission the frequency inverter's change signal, After judging by microcomputer and comparing the setting pressure. send one changing frequency command to the controller . The controller change the pump motor speed and the number of running by changing the frequency automatically adjust the peak water consumption, to ensure the water supply network pressure constant and meet the needs of users 'water.

Application Range

- Urban and rural residential area, high-rise buildings water supply, hotels, restaurants and large-sized structures' water supply and fire fighting water;

- City central heating water supply and air-conditioning system of hot and cold water circulation system.

- Water pumping stations, pipeline system.

- Industrial production and water recycling water of industrial boiler water supply system.

- Sewage treatment system.

- Old water supply (pressure water tower high water-level and water tank supply) transformation.

- Agricultural irrigation, sprinkler irrigation and music fountain.

Place to be used:

Ambient temperature: -10∽50℃

Control mode: Outlet constant pressure

Pressure adjustment precision: <±0.01MPa

Altitude: Below 1000M

Power: Three phase 380V±10%

Vibration: <0.5G

•Advanced technology: Use of computer control to control the cabinet according to the pressure to achieve intelligent constant pressure variable water supply;

•Energy efficient: the system can set pressure on demand, the system automatically adjusts the pump speed according to the set pressure and the number of pumps running, so that the equipment are running in the best state of energy efficient;

•Stable water supply pressure: the system to achieve closed-loop control, can automatically adjust the difference between the set pressure and system pressure , maintain the pressure constant.

•Stable Operation: The system is controlled automatically by the inverter and inverter intelligent controller, the operation is extremely simple; extend the life time of motor pump. Each pump is soft starter . eliminating the impact of the starting current. Each pump cycle start, so that the standby pump will not rust or wear for using a long time

•Perfect protection function: Have short circuit ,over-current, over-voltage ,overload protection and other protection function, pump will stop working and alarm output automatically if the pump run failure; The system has a self-test fault ,diagnosis fault, memory display fault automatically start standby pump and other functions.

•Small flow sleep function: Can be connected with a small pump attached . the cabinet can shutdown the main pumps if the system is running in the night or other small flow conditions . start the subsidiary pump, to avoid the waster caused by big power pumps.

•Operation function: The frequency inverter and the controller programming and parameter setting are convenient and simple, easy understanding .

•Manual automatic switching function: have manual switch control, you can ensure the safety and continuous operation of equipment.

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

Release Date:2025-10-15> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

Release Date:2025-10-09> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

Release Date:2025-09-25> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...

Release Date:2025-09-18