ZVF510 series frequency inverter is a new design of compact and economic inverter, with economic, small, easy to use, reliable features, excellent performance, rich features, widely used in logistics equipment, textile equipment, packaging equipment, music fountain and other industries.

Economic Save on equipment costs and increase lifecycle through technological innovation and experience-optimised design.

Mini Type Support seamless side-by-side installation in a small space, even plate cooling technology, multi-axis installation to save the cost of electrical cabinet.

Easy Use Network communication network, keyboard easy speed control; built-in macro applications, support for one-key setup parameters, saving equipment debugging labour costs.

cost.

Reliable Independent air ducts, triple-proof paint on the drive plate, intelligent fan, blocking protection, slip start, stable operation to reduce the loss of downtime.

Main Features

1. ZVF510 Series Frequency inverter are High power density design, Effectively realize small size, full power section book-type structure design, support seamless side-by-side installation in a small space.

2. Totally enclosed shell + independent air duct design.

More effective isolation of dust, to ensure the long-term stable operation of electronic components.

3. Large margin design,higher overload current, shorter acceleration time.

4. Built-in industry professional macro application, support one key to set industry parameters.

5. Standard Modbus communication, easy to realize industrial automation network.

Application Range

Common general purpose applications: fans, pumps, assembly line conveyors, etc.

Specialized occasions: constant pressure water supply, engraving machine, etc.

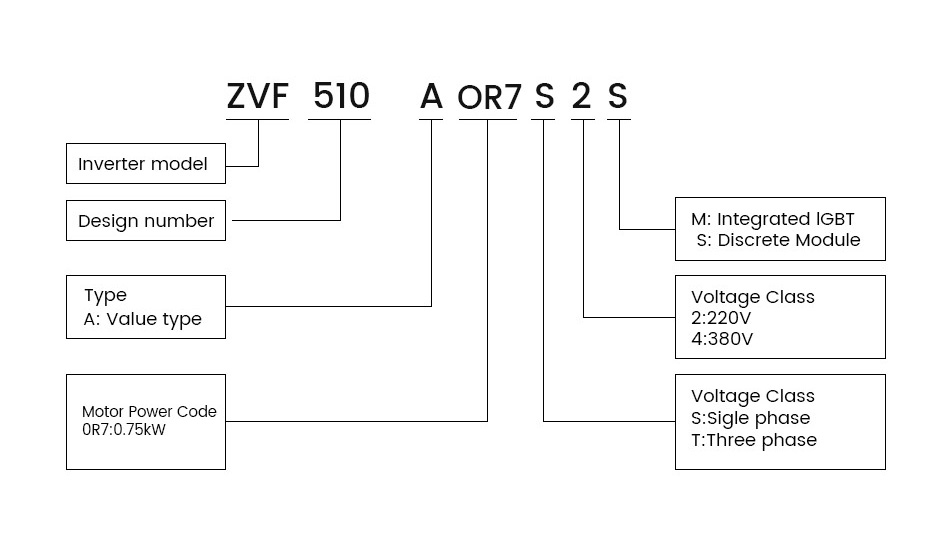

Demonstration of the model

ZVF 510 Series Frequency Converter

|

Input Voltage (V) |

Output Voltage(V) |

Power Range (kW) |

|

Single phase 200~240V |

Three phase 0~Input Voltage |

0.4~3.0kW |

|

|

Three phase 200~240V |

Three phase 0~Input Voltage |

0.4kW~5.5kW |

|

|

Three phase 360~440V |

Three phase 0~Input Voltage |

0.75kW~11kW |

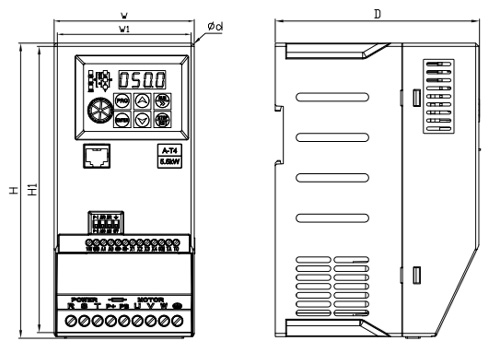

Outline & Mounting Dimension (Unit:mm)

|

Inverter Model |

Voltage (V) |

Power |

Current |

Dimension (mm) |

Figure |

|||||

|

(KW) |

( A) |

H |

H1 |

W |

W1 |

D |

d |

|||

|

ZVF510-A0R4S2S |

220V |

0.4 |

2.4 |

146 |

136.5 |

72 |

63 |

105 |

φ4.5 |

Fig.1 |

|

ZVF510-A0R7S2S |

220V |

0.75 |

4.5 |

|||||||

|

ZVF510-A1R5S2S |

220V |

1.5 |

7.0 |

|||||||

|

ZVF510-A2R2S2S |

220V |

2.2 |

10 |

|||||||

|

ZVF510-A3R0S2S |

220V |

3.0 |

11 |

182 |

172.5 |

87 |

78 |

127 |

φ4.5 |

Fig.2 |

|

ZVF510-A0R7T4S |

380V |

0.75 |

2.5 |

146 |

136.5 |

72 |

63 |

105 |

φ4.5 |

Fig.1 |

|

ZVF510-A1R5T4S |

380V |

1.5 |

3.7 |

|||||||

|

ZVF510-A2R2T4S |

380V |

2.2 |

5.0 |

|||||||

|

ZVF510-A3R0T4S |

380V |

3.0 |

6.8 |

|||||||

|

ZVF510-A4R0T4SD |

380V |

4.0 |

9.0 |

182 |

172.5 |

87 |

78 |

127 |

φ4.5 |

Fig.2 |

|

ZVF510-A5R5T4SD |

380V |

5.5 |

13 |

|||||||

|

ZVF510-A7R5T4SD |

380V |

7.5 |

17 |

240 |

229 |

118 |

106 |

155 |

φ5.5 |

Fig.3 |

|

ZVF510-A011T4SD |

380V |

11 |

24 |

|||||||

Three phase 220V

|

Inverter Model |

Voltage (V) |

Power |

Current |

Dimension (mm) |

Figure |

|||||

|

(KW) |

( A) |

H |

H1 |

W |

W1 |

D |

d |

|||

|

ZVF510-A0R4T2S |

220V |

0.4 |

2.4 |

146 |

136.5 |

72 |

63 |

105 |

φ4.5 |

Fig.1 |

|

ZVF510-A0R7T2S |

220V |

0.75 |

4.5 |

|||||||

|

ZVF510-A1R5T2S |

220V |

1.5 |

7.0 |

|||||||

|

ZVF510-A2R2T2S |

220V |

2.2 |

10 |

|||||||

|

ZVF510-A3R0T2SD |

220V |

3.0 |

11 |

182 |

172.5 |

87 |

78 |

127 |

φ4.5 |

Fig.2 |

|

ZVF510-A4R0T2SD |

220V |

4.0 |

16 |

240 |

229 |

118 |

106 |

155 |

φ5.5 |

Fig.3 |

|

ZVF510-A5R5T2SD |

220V |

5.5 |

20 |

|||||||

Optional Parts

|

ZVF510 keypad |

Remote Control Cable |

|

|

|

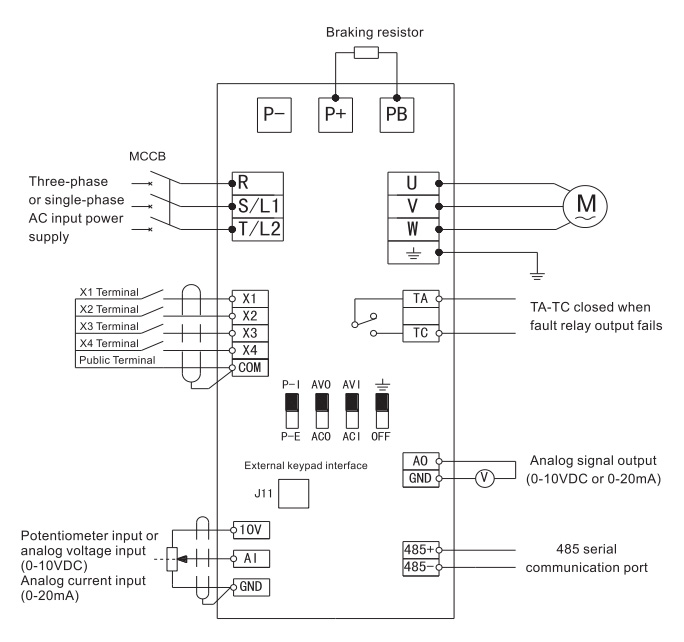

ZVF510 Frequency inverter's Standard Wiring Diagram

|

Item |

Item Description |

|

|

Input |

Rated voltage & Frequency |

Single-phase/3 Phase 200-240VAC, 3 Phase 360-440VAC,50/60Hz |

|

Allowable voltage working range |

Voltage fluctuation range:±10% Voltage unbalance rate: <3%, Frequency fluctuation:≤±5% |

|

|

Output |

Rated voltage |

3 Phase 0~Input voltage VAC |

|

Frequency |

0.0~600Hz |

|

|

Overload capacity |

110% long-term,150%1minute,180% 5 seconds |

|

|

Control your performance |

Control mode |

V/F control, Simple vector control, Advanced vector control, Torque control |

|

Frequency resolution |

Digital setting:0.1Hz Analog setting: Maximum frequency×0.1% |

|

|

Frequency accuracy |

Digital setting:0.1Hz Analog setting: within 0.2% of the maximum output frequency |

|

|

V/F Voltage frequency characteristic |

Three modes: the first is a linear torque characteristic curve, the second is a square torque characteristic curve, and the third is a user-set V/F curve. |

|

|

Automatic limit current and limit voltage |

No matter in the process of acceleration, deceleration or stable operation, it will automatically detect the motor stator current and voltage, and suppress it within the allowable range according to the unique algorithm, minimizing the possibility of system fault tripping. |

|

|

Vector voltage-frequency characteristics |

Automatically adjust output voltage-frequency ratio according to motor parameters and unique algorithm |

|

|

Torque characteristics |

Starting torque: 100% rated torque at 5.0Hz (VF control) 150% rated torque at 1.0Hz (vector control) |

|

|

Current and voltage suppression |

Full current closed-loop control, completely avoid current impact, with perfect overcurrent and overvoltage suppression function |

|

|

Under voltage suppression during operation |

Especially for users with low grid voltage and frequent grid voltage fluctuations, even if the voltage is lower than the allowable range, the system can maintain the longest possible running time according to the unique algorithm and residual energy allocation strategy |

|

|

Slip compensation |

Setting range: 0~100%, can automatically adjust the output frequency of the inverter according to the motor load, and reduce the rotation speed change of the motor caused by the load change |

|

|

Carrier frequency |

2.0~20.0KHz |

|

|

Automatic voltage regulation operation |

Dynamic voltage stabilization, static voltage stabilization, and no voltage stabilization can be selected according to the need to obtain the most stable operation effect. |

|

|

Built-in PID |

It can easily constitute a closed-loop control system, suitable for process control such as pressure control and flow control |

|

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

Release Date:2025-10-15> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

Release Date:2025-10-09> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

Release Date:2025-09-25> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...

Release Date:2025-09-18