Application of frequency converter in ventilator control

The working principle of the frequency converter

A frequency converter is a device that controls the speed of a motor by changing the frequency of the power supply. In a ventilator system, the frequency converter can adjust the running speed of the motor according to the actual demand, thus changing the air output of the ventilator. This type of adjustment is more accurate and efficient than the traditional baffle or valve adjustment.

Application of frequency converter in ventilator control

In ventilation systems, frequency converters are able to adjust the operating speed of ventilation fans in real time according to environmental conditions and actual demand. For example, in areas with a high concentration of people or large temperature variations, by increasing or decreasing the speed of the ventilator, the air circulation and temperature in the room can be quickly adjusted to provide a more comfortable environment.

In addition, the frequency converter can help reduce the starting current of the ventilator, reduce the impact on the power grid and extend the service life of the equipment. Through Inverter's soft start function, the inverter can slowly increase the running speed of the motor, avoiding damage to the motor and the power grid caused by sudden high currents.

1.Energy saving effect and operation stability of frequency converter

Controlling ventilators with frequency converters can significantly reduce energy consumption. In traditional control methods, ventilators usually run at a constant speed, regardless of the actual demand. With a frequency converter, we can adjust the operating speed of the ventilator according to the actual demand, avoiding unnecessary energy waste.

At the same time, the frequency converter can also improve the operational stability of the ventilator. By monitoring and adjusting the motor's operating status in real time, the frequency converter ensures that the ventilator operates at the optimal operating point and reduces the likelihood of failure.

In summary, the inverter plays an important role in ventilator control. It not only provides accurate airflow control, but also significantly improves energy efficiency and operational stability. In the future design of ventilation systems, more consideration should be given to the use of inverters to optimise system performance and efficiency.

2.Analysis of the energy-saving optimisation and application of Purple Sun inverters in industrial ventilation systems

• Core requirements for frequency control of ventilation systems

1. Load Characteristics

• Fans are square torque loads (Q∝n, H∝n²)

Usually operates at 50%~80% of rated airflow, there is a large space for energy saving

2.Control difficulties

• need to cope with changes in network resistance (e.g. clogged filters)

•Surge risk when multiple turbines are connected in parallel

Key Technology Adaptation of CHZIRI Frequency Inverter

1. Hardware matching programme

|

CHZIRI inverter |

Recommended power range |

Type of ventilation equipment |

|

ZVF300H |

0.75-55kW |

Roof fans/smoke exhaust fans

|

|

ZVF300H |

75-315kW |

Tunnel jet fan |

|

ZVF300H |

355-630kW |

Main mine ventilation fan |

Critical function validation:

• Built-in PID regulation (supports air pressure/air volume closed-loop control)

• Automatic energy-saving search

Instantaneous power failure restart function

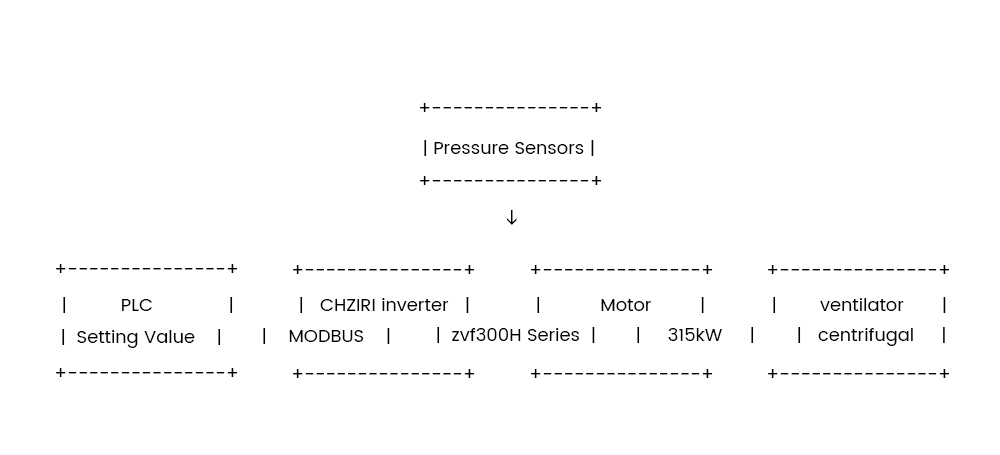

2.Typical Control Logic

3.Comparison of energy saving effect(Example)

Data on the retrofit of a 55kW induced draft fan in a chemical plant:

|

Running Mode |

Average daily power consumption(kWh) |

Throttle valve opening

|

|

Working frequency operation

|

892 |

60% |

|

Variable frequency control |

537 |

100% |

|

Energy Savings Rates:Annual electricity cost saving of about CNY62,000 |

||

Maintenance Points

• l Check cooling fan status monthly

• l Quarterly cleaning of air duct dust (shorter cycle for textile mills)