1. With two models of external bypass and internal bypass, it is convenient for customers to choose.

2. Main terminal connecting line is fixed directly by screws, which is safe and reliable.

3. The control line alone power supply is more stable, can make the main power supply range covers 220-480V without changing the machine.

4. LCD display, standard Chinese and English options, more convenient to use, can also be customized according to customer requirements of other language types.

5. Three groups motor parameters can be switched, more convenient to use.

6. With PTC temperature sensor interface, motor protection is more comprehensive.

7. Equipped with RS485 communication interface as standard, it is more convenient for group network control.

8. 10 sets fault records, Easier to find problem .

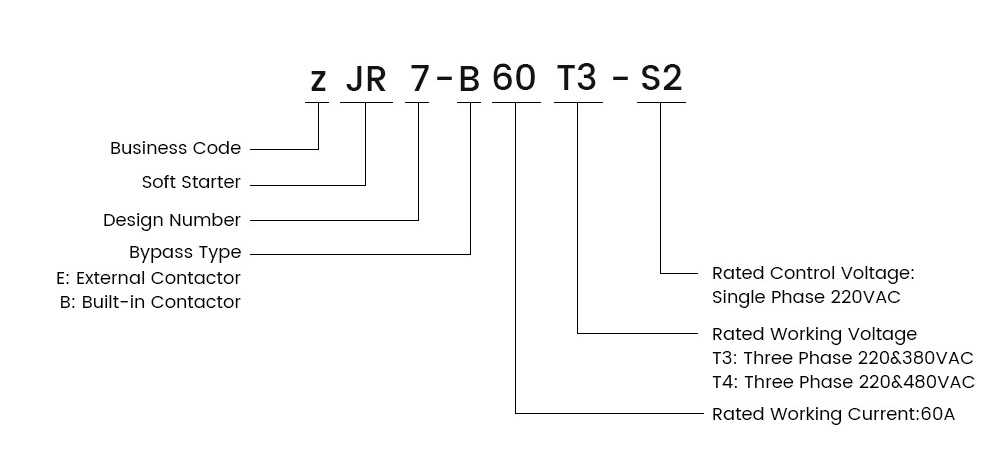

Model Description

ZJR7-B Series Built-in Contactor Soft Starter

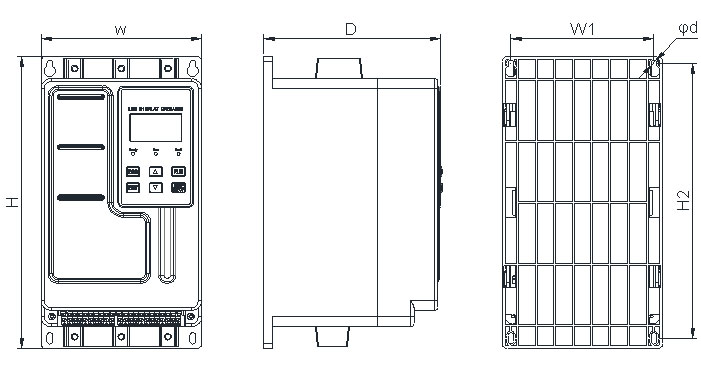

| Soft starter Model | Rated Power (kW) |

Rated Current (A) |

Outline Size(mm) | Install Size(mm) | ||||||

| H | H1 | W | D | H2 | W1 | W2 | Φd | |||

| ZJR7-B11T3-S2 | 5.5kW | 11A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B15T3-S2 | 7.5kW | 15A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B22T3-S2 | 11kW | 22A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B30T3-S2 | 15kW | 30A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B37T3-S2 | 18.5kW | 37A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B44T3-S2 | 22kW | 44A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B60T3-S2 | 30kW | 60A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B74T3-S2 | 37kW | 74A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B90T3-S2 | 45kW | 90A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

| ZJR7-B110T3-S2 | 55kW | 110A | 290 | - | 155 | 170 | 272 | 138 | - | 5.5 |

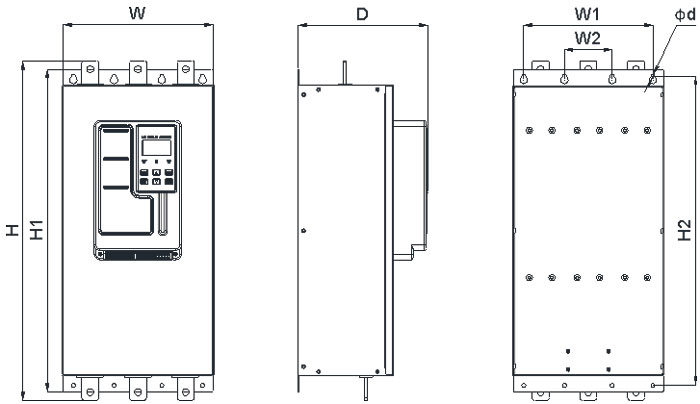

| Soft starter Model | Rated Power (KW) |

Rated Current (A) |

Outline Size(mm) | Install Size(mm) | ||||||

| H | H1 | W | D | H2 | W1 | W2 | Φd | |||

| ZJR7-B150T3-S2 | 75kW | 150A | 370 | 360 | 220 | 230 | 340 | 180 | - | 7 |

| ZJR7-B180T3-S2 | 90kW | 180A | 370 | 360 | 220 | 230 | 340 | 180 | - | 7 |

| ZJR7-B220T3-S2 | 110kW | 220A | 370 | 360 | 220 | 230 | 340 | 180 | - | 7 |

| ZJR7-B264T3-S2 | 132kW | 264A | 585 | 560 | 270 | 230 | 535 | 230 | - | 7 |

| ZJR7-B320T3-S2 | 160kW | 320A | 585 | 560 | 270 | 230 | 535 | 230 | - | 7 |

| ZJR7-B370T3-S2 | 185kW | 370A | 585 | 560 | 270 | 230 | 535 | 230 | - | 7 |

| ZJR7-B400T3-S2 | 200kW | 400A | 585 | 560 | 270 | 230 | 535 | 230 | - | 7 |

| ZJR7-B440T3-S2 | 220kW | 440A | 585 | 560 | 270 | 230 | 535 | 230 | - | 7 |

| ZJR7-B500T3-S2 | 250kW | 500A | 660 | 620 | 310 | 230 | 595 | 270 | 100 | 7 |

| ZJR7-B560T3-S2 | 280kW | 560A | 660 | 620 | 310 | 230 | 595 | 270 | 100 | 7 |

| ZJR7-B630T3-S2 | 315kW | 630A | 660 | 620 | 310 | 230 | 595 | 270 | 100 | 7 |

| ZJR7-B710T3-S2 | 355kW | 710A | 690 | 650 | 350 | 230 | 625 | 300 | 110 | 9 |

| ZJR7-B800T3-S2 | 400kW | 800A | 690 | 650 | 350 | 230 | 625 | 300 | 110 | 9 |

| ZJR7-B900T3-S2 | 450kW | 900A | 690 | 650 | 350 | 230 | 625 | 300 | 110 | 9 |

| ZJR7-B1000T3-S2 | 500kW | 1000A | 740 | 700 | 420 | 230 | 675 | 370 | 135 | 9 |

| ZJR7-B1120T3-S2 | 560kW | 1120A | 740 | 700 | 420 | 230 | 675 | 370 | 135 | 9 |

| ZJR7-B1260T3-S2 | 630kW | 1260A | 740 | 700 | 420 | 230 | 675 | 370 | 135 | 9 |

|

Item |

Item Description |

||

|

Rated working voltage |

Three Phase 220-480VAC±10%/50(60)Hz |

||

|

Rated limit short-circuit current |

20kA(400A and Below) |

30kA(400A and above) |

|

|

Coordination type |

Type I |

||

|

Use categories |

AC-53b |

||

|

Rated control supply voltage |

180-260VAC |

||

|

Rated insulation voltage |

660V |

||

|

Applicable motors |

Squirrel-cage three-phase asynchronous motors |

||

|

Number of starts |

It's recommended that No more than 5 times per hour, the number of starts can be set in the parameters |

||

|

Control mode |

(1) Operation panel control; (2) External terminal control; (3) Communication control |

||

|

Start Mode |

⑴Voltage ramp starting; ⑵Torque Start; ⑶Kick start+Voltage ramp Start ⑷Kick start +torque start |

||

|

Stop Mode |

⑴Soft Stop ;⑵ Free Stop |

||

|

Protection Function |

⑴Instantaneous stop terminal open circuit fault; ⑵Soft starter overheating; ⑶Motor overheating; ⑷Input Phase loss; (5)Output phase loss; ⑹Three phase unbalance; ⑺Underload protection; ⑻Overload protection; ⑼The power supply voltage is too low; ⑽The power supply voltage is too high; ⑾Error setting parameters; ⑿The load is shorted circuit ; ⒀frequency error; ⒁External faults; ⒂ The starting time is too long; ⒃ Too many starting times and etc. |

||

|

Ambient |

Place to be used |

Indoor; no corrosive gases, no conductive dust; well ventilated. |

|

|

Altitude |

The altitude does not exceed 1000m, if it exceeds 1000m and is less than 3000m, the current is reduced by 1% for each additional 100m. |

||

|

Ambient temperature |

Ambient temperature should be between -10℃~+40℃, +40℃~+50℃ should be derated, the current is derated by 2% for every 1℃ rise in temperature. |

||

|

Ambient humidity |

The relative humidity is no more than 90%, without dew condensation . |

||

|

Vibration |

Vibration force should be below 0.5G |

||

|

Structure |

Protection Class |

IP20 |

|

|

Cooling Mode |

Natural air cooling |

||

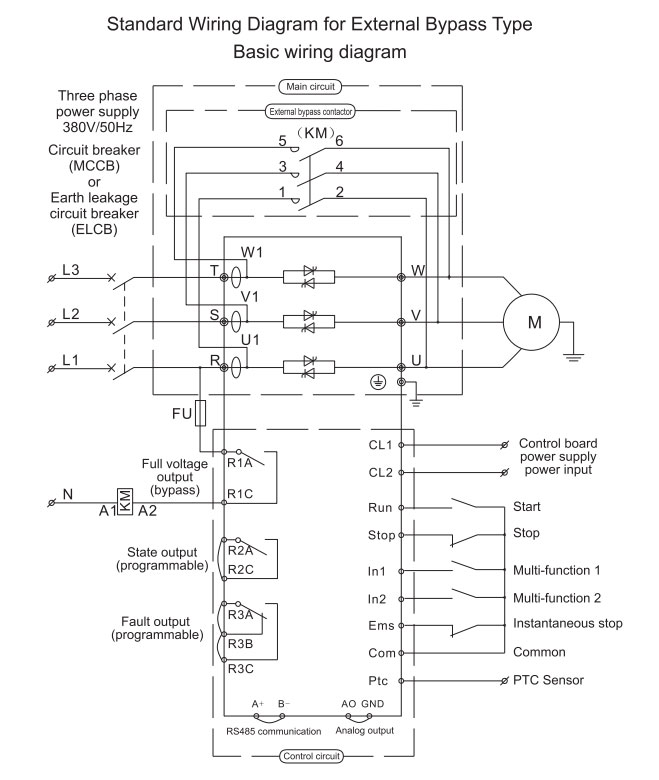

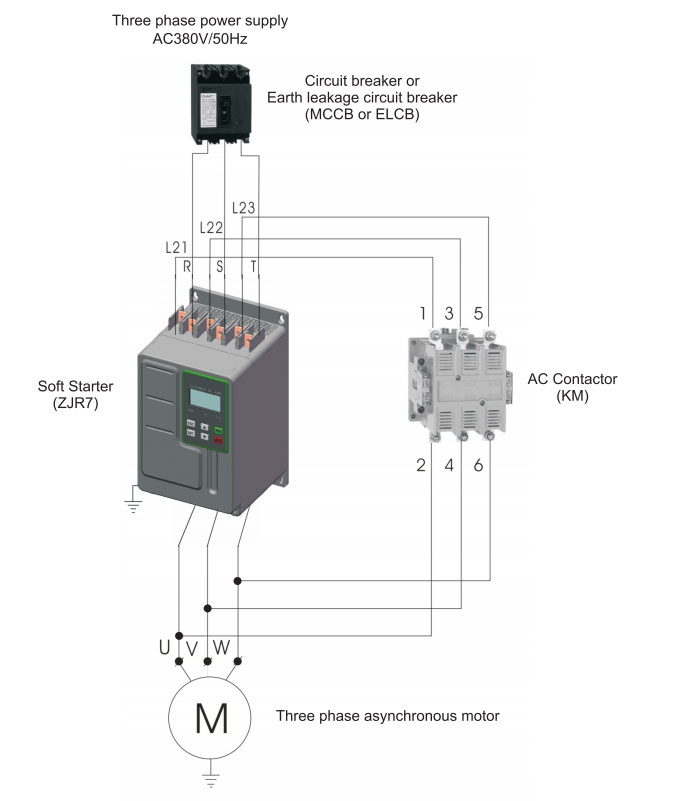

Standard Wiring Diagram

Main Circuit Connection Diagram for built-in bypass Contactor Type

Application Settings

As load conditions change,parameters often need to be adjusted. The following table is for reference only.

|

Application |

Starting boost time (s) |

Stop depressurization time (s) |

Starting voltage (%) |

Voltage starting (current limit value) |

|

Centrifugal Pump |

16 |

20 |

40 |

4 |

|

Ball Mill |

20 |

6 |

60 |

4 |

|

Fan |

26 |

4 |

30 |

4 |

|

Piston Compressor |

16 |

4 |

40 |

3 |

|

Light Load Motor |

16 |

2 |

30 |

3 |

|

Lifting Machinery |

6 |

10 |

60 |

3.5 |

|

Mixer |

16 |

2 |

50 |

4 |

|

Crusher |

16 |

10 |

50 |

4 |

|

Screw Compressor |

16 |

2 |

40 |

3 |

|

Spiral Conveyor Belt |

20 |

10 |

40 |

4 |

|

Belt Conveyor Belt |

20 |

10 |

40 |

3 |

|

Heat Pump |

16 |

20 |

40 |

3 |

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

Release Date:2025-10-15> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

Release Date:2025-10-09> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

Release Date:2025-09-25> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...

Release Date:2025-09-18