ZJR2 Series motor soft starter is suitable for three phase.AC squirrel cage induction asynchronous motor, the voltage is 320V~ 460V.50(60)Hz. The rated current is 1200A and below. The soft starter is assembled type, need to add breakers (short circuit protection )and AC contactor ( Bypass ) inside the cabinet, together with switches are made up of electric motor control circuit. It’s no need to install the thermal relay, there have perfect motor protection function while the motor start and running, adapt closed-loop control, improve the stationarity and reliability of the motor 's soft torque start and soft torque stop.Use By-pass contactor when running. The running power is almost zero. It can improve the reliability of the soft starter and reduce the overall size.

1.16 SCM control, intelligent all-digital display.

2.Can be put into practice a soft starter control multiple motors.

3.Starting modes: Current limiting starter. Voltage ramp start, Kick start +current-limiting start, Kick start +voltage ramp start. Current ramp start. Voltage current-limiting double closed-loop start.

4.Free stop and soft stop. The stop time from 0 to 60 seconds can be arbitrary selected .

5.Over current. Overload. Open phase, instantaneous stop and other fault protection, with the flow, lack phase, instantaneous stop, and other malfunction protection.

6.Easy installation, simple operation, strong function and reasonable price.

7.5.5kW-55kW soft starter also have built-in bypass contactor. But the factory default is not with built-in bypass contactor. Clients need to confirm this once order confirmed.

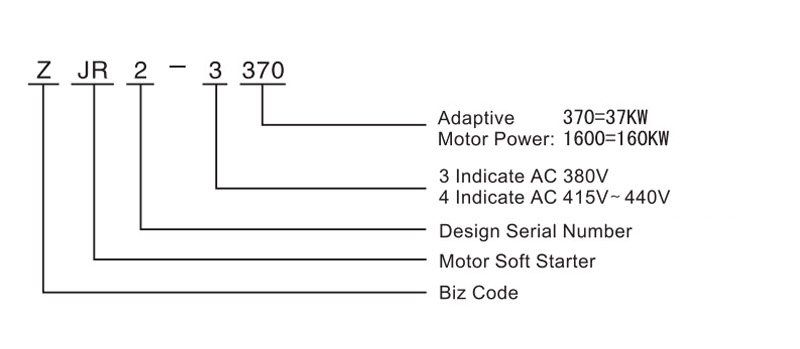

Demonstration of the Model

Application Range

ZJR2 series soft starter can meet the requirements of following loads:

centrifugal pump, bill grinder, fan ,piston compressor, light load motor ,hoist machinery, mixer, crusher screw compressor, screw conveyor belt, belt, conveyor and heat pump and so on.

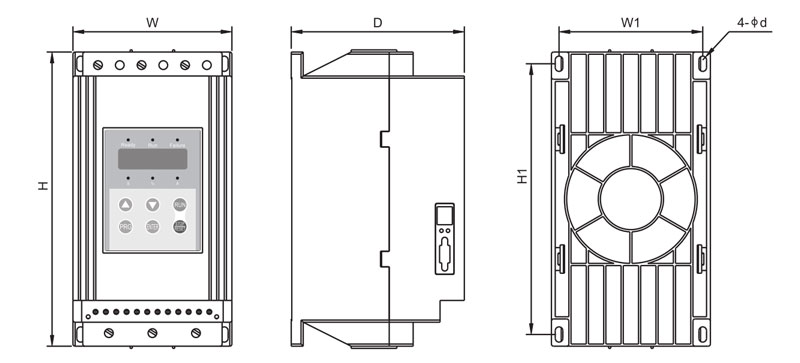

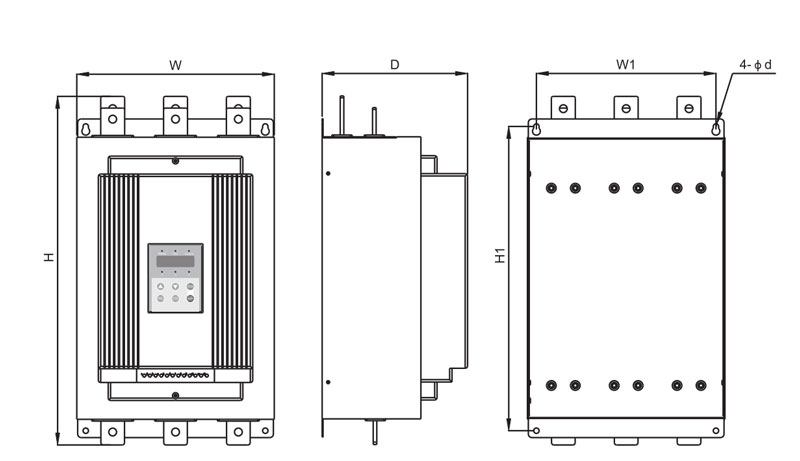

Soft Starter Outline & Mounting Dimension (Unit:mm)

Motor Guide for ZJR2 Soft Starter

Power Range:5.5kW~55kW

|

Model |

Rated Power(KW) |

Rated Current (A) |

Outline Size |

Install Size |

||||

|

H1 |

W1 |

D |

H2 |

W2 |

d |

|||

|

ZJR2-3055/4055 |

5.5 kW |

11 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3075/4075 |

7.5 kW |

15 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3110/4110 |

11 kW |

23 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3150/4150 |

15 kW |

30 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3185/4185 |

18.5 kW |

37 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3220/4220 |

22 kW |

43 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3300/4300 |

30 kW |

60 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3370/4370 |

37 kW |

75 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3450/4450 |

45 kW |

90 A |

270 |

145 |

159 |

245 |

130 |

7 |

|

ZJR2-3550/4450 |

55 kW |

110A |

270 |

145 |

159 |

245 |

130 |

7 |

Power Range :75kW~600kW

|

Model |

Rated Power(kW) |

Rated Current (A) |

Outline Size |

Install Size |

||||

|

H1 |

W1 |

D |

H2 |

W2 |

d |

|||

|

ZJR2-3750/4750 |

75 kW |

150 A |

530 |

260 |

202 |

380 |

235 |

10 |

|

ZJR2-3900/4900 |

90 kW |

180A |

530 |

260 |

202 |

380 |

235 |

10 |

|

ZJR2-31150/41150 |

115 kW |

230 A |

530 |

260 |

202 |

380 |

235 |

10 |

|

ZJR2-31320/41320 |

132 kW |

264 A |

530 |

260 |

202 |

380 |

235 |

10 |

|

ZJR2-31600/41600 |

160 kW |

320 A |

530 |

260 |

202 |

380 |

235 |

10 |

|

ZJR2-32000/42000 |

200 kW |

400 A |

530 |

260 |

202 |

380 |

235 |

10 |

|

ZJR2-32500//42500 |

250 kW |

500 A |

560 |

290 |

245 |

460 |

260 |

10 |

|

ZJR2-32800/42800 |

280 kW |

560 A |

560 |

290 |

245 |

460 |

260 |

10 |

|

ZJR2-33200/43200 |

320 kW |

640 A |

560 |

290 |

245 |

460 |

260 |

10 |

|

ZJR2-34000/44000 |

400 kW |

800 A |

600 |

330 |

245 |

500 |

300 |

10 |

|

ZJR2-34500/44500 |

450 kW |

900 A |

600 |

330 |

245 |

500 |

300 |

10 |

|

ZJR2-35000/45000 |

500 kW |

1000A |

760 |

406 |

260 |

540 |

370 |

10 |

|

ZJR2-36000/46000 |

600 kW |

1200A |

760 |

406 |

260 |

540 |

370 |

10 |

|

Item |

Item Description |

||

|

Input Power Supply |

Input Voltage |

Three phase 320V~ 460VAC |

|

|

Frequency |

50/60Hz |

||

|

Adaptive Motor |

Squirrel-cage three-phase asynchronous motor |

||

|

Starting Times |

It is recommended not to exceed 20 times per hour. |

||

|

Control Mode |

1)Operation panel control;2) Operation panel + external control;3)External control;4) External control + COM control;5)Operation panel + external + COM control;6) Operation panel + COM control;7) COM control;8) No start or stop operation. |

||

|

Start Mode |

1)Current-limiting start;2) Voltage ramp start;3) Kick start + current-limiting start;4) Kick start + voltage ramp start;5) Current ramp start;6) Voltage current-limiting double closed-loop start. |

||

|

Stop Mode |

1) Soft stop; 2) Free stop. |

||

|

Protective Function |

1) Open loop protection for external instantaneous stop terminals; 2) Over-heat protection for soft starter; 3) Protection for too long starting time; 4) Input open phase protection; 5) Output open phase protection; 6) Unbalanced three-phase protection; 7) starting over current protection; 8) Running overload protection; 9) Under voltage protection for power voltage; 10) Over voltage protection for power voltage; 11) Protection for fault parameter setting; 12) Load short circuit protection; 13) Auto restart or incorrect wiring protection; 14) Incorrect wiring protection of external control stop terminals. |

||

|

Ambient |

Place to be used |

Indoor location with good ventilation free from corrosive gas and conductive dust. |

|

|

Altitude |

Below 3000M. It have to rise the rate power when the altitude is more than 3000M. |

||

|

Ambient Temperature |

-30~+55℃ |

||

|

Ambient Humidity |

≤90%RH without dew condensation. |

||

|

Vibration |

<0.5G |

||

|

Structure |

Protection Class |

IP20 |

|

|

Cooling Pattern |

Natural wind cooling. |

||

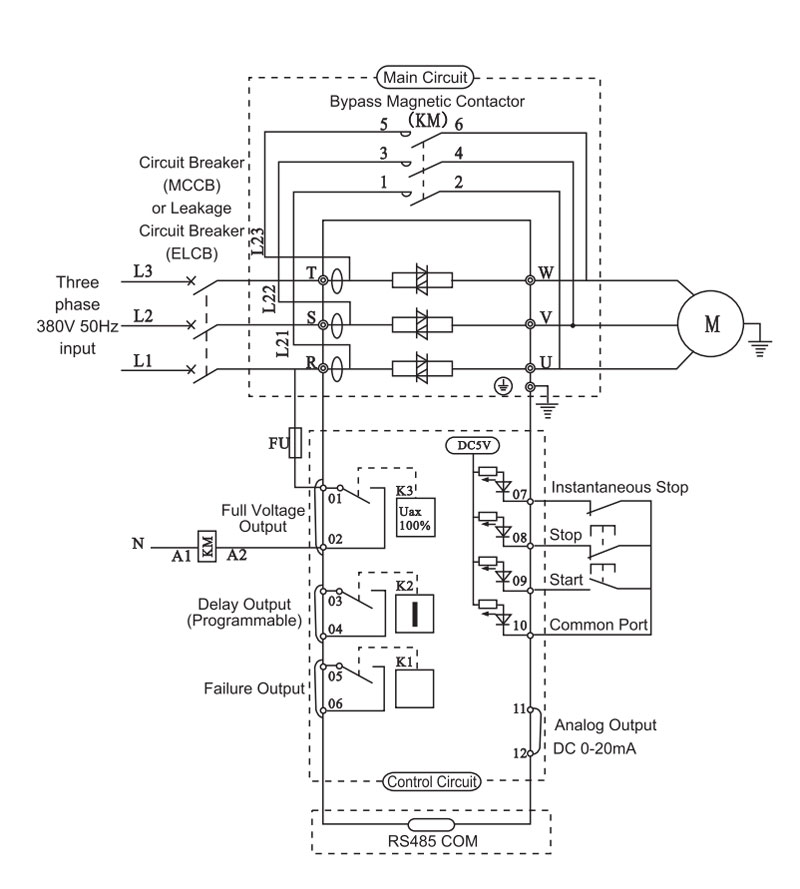

Basic Wiring Diagram ZJR2 soft starter external contactor

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

Release Date:2025-10-15> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

Release Date:2025-10-09> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

Release Date:2025-09-25> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...

Release Date:2025-09-18