Features

The sine wave filter transforms the PWM Output signal of the electro motor into a smooth sine wave of the low residual ripple voltage so as to prevent the damaged to the winding insulation of the motor. It also reduces the occurrence of the distributed capacitance cause by the over-length of cable and the phenomenon of resonances which is resulted from distributed inductance . Besides .It eliminates the over-voltage of the motor caused by high dv/dt, spares the damage of the motor in advance resulted from the eddy-current loss .the sine wave filter also reduces the perceivable noise of the electro motor.

This sine wave filter adopts the foil winding structure and the copper bar leading-out .It is featured with DC resistance . Strong resistance to electromagnetism and excellent overload ability in short time .The usage of F or above grade composite insulating materials with high performance allows for the reliable performance of the equipment under harsh working conditions .Its strong insulating strength makes it possible to bear ultra high voltage shock . The vacuum pressure impregnation process adopted in this sine wave filter reduces the perceivable noise to a low degree.

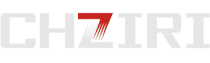

Electrical Schematic Diagrams

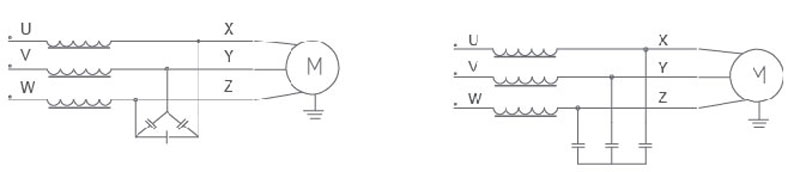

Outline & Mounting Dimension(Unit:mm)

Output 380V Sine Filter Selection Model

| Type | Power (kW) | Rated Current (A) | Picture | Dimension (±0.5mm) | Gross weight (kg) | ||||

| D*H*W(mm) | D1*W1 (mm) |

a*b (mm) |

∮c c(mm) |

A*e (mm) |

|||||

| OSF-0015-EISA-E4M0 | 5.5 | 15A | A | 250*270*200 | 182*91 | 11*18 | / | / | 18 |

| OSF-0020-EISA-E3M0 | 7.5 | 20A | 250*280*220 | 182*100 | 11*18 | / | / | 22 | |

| OSF-0030-EISA-E2M0 | 11 | 30A | 250*270*230 | 182*106 | 11*18 | / | / | 22 | |

| OSF-0040-EISA-E1M4 | 15 | 40A | 250*280*240 | 182*121 | 11*18 | / | / | 26 | |

| OSF-0050-EISA-E1M2 | 18.5 | 50A | 290*290*230 | 214*110 | 11*18 | / | / | 26 | |

| OSF-0060-EISA-E1M0 | 22 | 60A | 290*290*300 | 214*120 | 11*18 | / | / | 31 | |

| OSF-0080-EISA-EM80 | 30 | 80A | 320*320*320 | 243*142 | 12*20 | / | / | 45 | |

| OSF-0090-EISA-EM65 | 37 | 90A | B | 320*500*270 | 243*159 | 12*20 | Φ11 | 25*5 | 59 |

| OSF-0120-EISA-EM52 | 45 | 120A | 320*510*300 | 243*169 | 12*20 | Φ11 | 25*5 | 62 | |

| OSF-0150-EISA-EM45 | 55 | 150A | 395*590*295 | 225*175 | 15*25 | Φ11 | 25*5 | 77 | |

| OSF-0200-EISA-EM35 | 75 | 200A | 400*620*320 | 225*200 | 15*25 | Φ11 | 30*5 | 94 | |

| OSF-0250-EISA-EM30 | 110 | 250A | 400*680*345 | 225*225 | 15*25 | Φ11 | 30*5 | 110 | |

| OSF-0300-EISA-EM24 | 132 | 300A | 405*720*360 | 225*225 | 15*25 | Φ11 | 30*6 | 121 | |

| OSF-0360-EISA-EM20 | 160 | 360A | 430*720*390 | 245*250 | 15*25 | Φ13 | 40*5 | 158 | |

| OSF-0450-EISA-EM15 | 200 | 450A | 430*720*400 | 250*250 | 15*25 | Φ14 | 40*5 | 169 | |

| OSF-0500-EISA-EM15 | 250 | 500A | 460*800*390 | 270*250 | 15*25 | Φ14 | 50*5 | 197 | |

| OSF-0600-EISA-EM12 | 280 | 600A | 480*860*400 | 275*250 | 15*25 | Φ14 | 50*5 | 243 | |

| OSF-0660-EISA-EM10 | 315 | 660A | 470*780*440 | 300*250 | 15*25 | Φ14 | 50*5 | 257 | |

| OSF-0750-EISA-EM09 | 355 | 750A | 550*900*440 | 275*300 | 15*25 | Φ14 | 50*10 | 284 | |

| OSF-0900-EISA-E75U | 400 | 900A | C | 550*940*470 | 275*300 | 15*25 | Φ13 | 60*10 | 317 |

| OSF-1000-EISA-E60U | 450 | 1000A | 550*945*470 | 275*300 | 15*25 | Φ13 | 60*10 | 274 | |

| OSF-1200-EISA-E65U | 500 | 1200A | 600*1010*490 | 300*300 | 15*25 | Φ13 | 80*8 | 412 | |

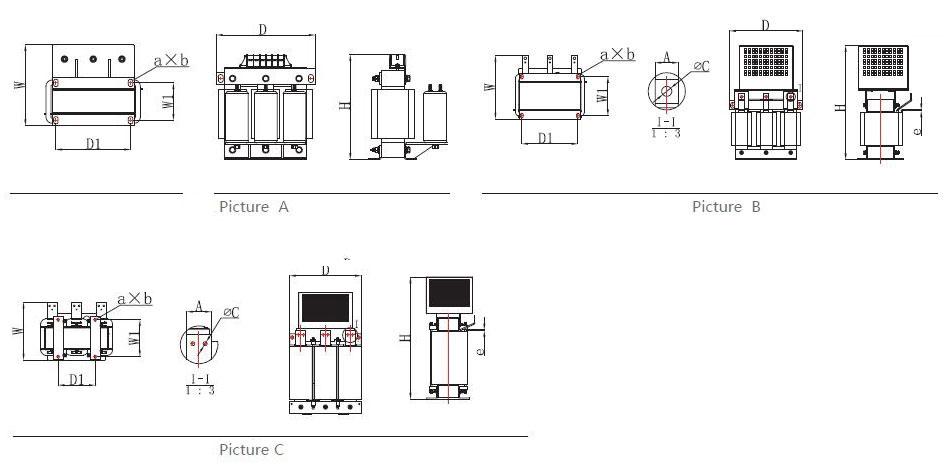

Wiring Diagram for Inverter System

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...