Product introduction

The wirewound resistor is made by fixing two leading-out terminals on the cylindrical ceramic tube which is coiled by bandlet and wave shape alloy resistance wire. The surface of the ceramic tube is coated by layer of coating which is resistant to flaming and high temperature. As the framework of the resistance wire. The ceramic tube can also work as the radiator .this product can be made to order .It is suitable for simulated load test .the discharging of equipment .automatic control and the dynamic braking of the transducer.

Two terminal extensions are fixed on both ends of a ceramic tube on whose surface winds wave-shaped alloy resistance wire and a high temperature-resistant and fireproof coating are applied. The ceramic tube can function as resistance wire skeleton and heat radiator as well . This product can be customized to special needs of customers and applicable to simulation load test, equipped discharge, automated control and inverter’s energy loss brake.

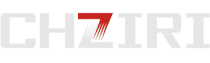

Technical Data:

Rated Power Range: 50W-2500W

Voltage Range: 0.5KV—10KV

Resistance Range: 1R-1KR

Dielectric Voltage: AC2.5KV-20KV/1min 50Hz

IP Class: IP00

Vibration: 1g

Rated Temperature Rise: 375℃

Temperature Coefficient: 80-400ppm/℃

Carrier Material: 0Cr25AL5/Ni80Cr20 Optional

Advantage: Work in high voltage

Disadvantage: Inferior vibration

Packing: Paper box

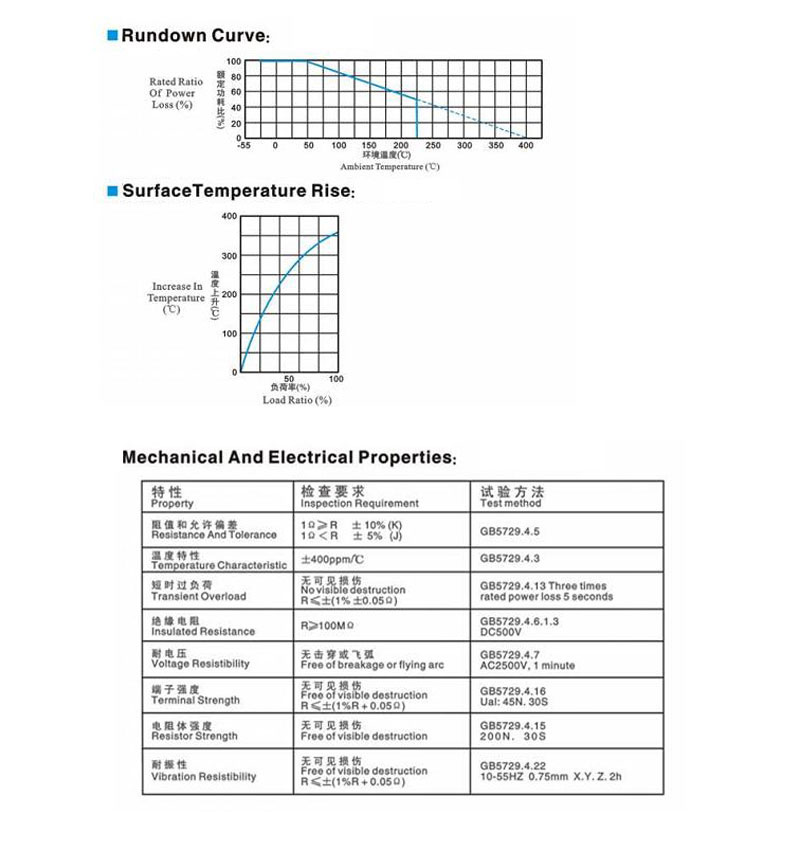

Outline& Mounting Dimension (Unit:mm)

|

Rated power (w) |

Dimension(mm) |

||||||||||

|

L1(±2) |

L2(±5) |

L3(±3) |

D(±2) |

B |

B1 |

H |

H1(±3) |

N |

¢d |

O |

|

|

50 |

102 |

124 |

146 |

28 |

6.5 |

28 |

28 |

61 |

10 |

4.5 |

1.2 |

|

60 |

102 |

124 |

146 |

28 |

6.5 |

28 |

28 |

61 |

10 |

4.5 |

1.2 |

|

80 |

152 |

174 |

196 |

28 |

6.5 |

28 |

28 |

61 |

10 |

4.5 |

1.2 |

|

100 |

182 |

204 |

226 |

28 |

6.5 |

28 |

28 |

61 |

10 |

4.5 |

1.2 |

|

120 |

182 |

204 |

226 |

28 |

6.5 |

28 |

28 |

61 |

10 |

4.5 |

1.2 |

|

150 |

195 |

217 |

239 |

40 |

8 |

40 |

41 |

81 |

12 |

5.5 |

2.0 |

|

200 |

195 |

217 |

239 |

40 |

8 |

40 |

41 |

81 |

12 |

5.5 |

2.0 |

|

300 |

282 |

304 |

326 |

40 |

8 |

40 |

41 |

81 |

12 |

5.5 |

2.0 |

|

400 |

282 |

304 |

326 |

40 |

8 |

40 |

41 |

81 |

12 |

5.5 |

2.0 |

|

500 |

316 |

338 |

360 |

50 |

8 |

50 |

45 |

101 |

16 |

6 |

2.0 |

|

600 |

345 |

367 |

389 |

40 |

8 |

40 |

41 |

81 |

12 |

5.5 |

2.0 |

|

750 |

316 |

338 |

360 |

50 |

8 |

50 |

45 |

101 |

16 |

6 |

2.0 |

|

1000 |

300 |

325 |

350 |

60 |

8.5 |

60 |

60 |

119 |

16 |

6 |

2.0 |

|

1200 |

415 |

440 |

465 |

60 |

8.5 |

60 |

60 |

119 |

16 |

6 |

2.0 |

|

1500 |

415 |

440 |

465 |

60 |

8.5 |

60 |

60 |

119 |

16 |

6 |

2.0 |

|

2000 |

510 |

535 |

560 |

60 |

8.5 |

60 |

60 |

119 |

16 |

6 |

2.0 |

|

2500 |

600 |

625 |

650 |

60 |

8.5 |

60 |

60 |

119 |

16 |

6 |

2.0 |

Note:For bigger power inverter ,we suggest you use braking resistor box.

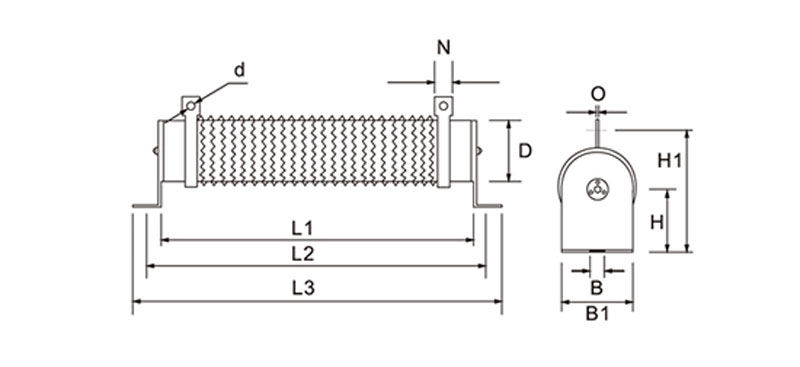

Wiring Diagram for Inverter System

Recommended brake assembly matching specification

| Inverter | Braking Unit | Braking resistor | ||||

| Voltage(V) | Motor(KW) | Model | Quantity(PCS) | Recommed resistor value | Resisitor specification | Quantity(PCS) |

| 220V | 0.75KW | Built-in | 80W200Ω | 80W200Ω | 1 | |

| 1.5KW | Built-in | 200W100Ω | 200W100Ω | 1 | ||

| 2.2KW | Built-in | 300W70Ω | 300W70Ω | 1 | ||

| 3.7KW | Built-in | 400W40Ω | 400W40Ω | 1 | ||

| 380V | 0.75KW | Built-in | 80W750Ω | 80W750Ω | 1 | |

| 1.5KW | Built-in | 200W400Ω | 200W400Ω | 1 | ||

| 2.2KW | Built-in | 300W250Ω | 300W250Ω | 1 | ||

| 3.7KW | Built-in | 400W150Ω | 400W150Ω | 1 | ||

| 5.5KW | Built-in | 600W100Ω | 600W100Ω | 1 | ||

| 7.5KW | Built-in | 800W75Ω | 800W75Ω | 1 | ||

| 11KW | Built-in | 1000W50Ω | 1000W50Ω | 1 | ||

| 15KW | Built-in | 1500W40Ω | 1500W40Ω | 1 | ||

| 18.5KW | 4030 | 1 | 2500W35Ω | 2500W35Ω | 1 | |

| 22KW | 4030 | 1 | 3000W27.2Ω | 3000W27.2Ω | 1 | |

| 30KW | 4030 | 1 | 5000W19.2Ω | 2500W38.4Ω | 2 | |

| 37KW | 4045 | 1 | 6000W16Ω | 2000W48Ω | 3 | |

| 45KW | 4045 | 2 | 9600W13.6Ω | 2500W54.4Ω | 4 | |

| 55KW | 4030 | 2 | 12000W10Ω | 2000W60Ω | 6 | |

| 75KW | 4045 | 2 | 19200W6.8Ω | 2500W54.4Ω | 8 | |

| Braking Resistor Box | Quantity(PCS) | |||||

| 90KW | 4030 | 3 | 9600W20Ω | 3 | ||

| 100KW | 4220 | 1 | 9600W20Ω | 3 | ||

| 132-160KW | 4220 | 1 | 40KW3.4Ω | 1 | ||

| 185-220KW | 4220 | 1 | 60KW3.2Ω | 1 | ||

| 250-315KW | 4220 | 2 | 40KW4.5Ω | 2 | ||

| 315-600KW | 4220 | 3 | 60KW3Ω | 3 | ||

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...