ZHG-9603 Series constant pressure pump controller is specialized for constant pressure water supply pump variable frequency controller. The constant pressure water supply controller can make the water supply system run steadily and reliably, and realize a true automatic cycle pump and variable frequency operation. to ensure the optimal running efficiency of each water pump and the stable operation of the equipment start smoothly. Eliminates high-current shocks and lowers the pump's average speed, extending pump life and eliminating water hammer during start-up and shutdown.

1. Include 3 units main pumps & one unit small pump, it has multiple controlling mode and meets all kinds of complex requests of pump.

2. Timing change pump function, balance all kinds of pumps' working time . improve the average life of the pumps.

3. Up to 8 periods pressure control, and each period can be set any pressure setting control .and realize the timer ON/OFF function .

4.Sleep function and auxiliary small pump function, save energy and reduce consumption , extend machine’s life.

5. Positive and negative feedback function , can be used for water supply, but also can be used to pump water and maintain the water level.

6.Over-pressure, low water level, sensor disconnection, inverter failure and alarm control functions ect.

7.Feedback can connect with passive remote pressure gauge, active voltage and current transmitter.

8. Feedback device power 0-24V can be modified, stronger commonality.

9. Feedback signals can be selected .it is more convenient to connect with outer .

10. Standard 0-10V voltage output, can also be arbitrarily modified to other voltage values, the application will be more flexible.

11.when the inverter get failure,The controller can choose the automatic transfer to the working frequency running (pressure range control)

12 .Relay fault output function can be selected.

13. Strong adaptable, applicable to various brands frequency inverter at home and abroad.

14.All digital signal use photoelectric isolation, strong interference ability .

15.With complete key function.

|

Item |

Item Description |

|

Input Power Specification |

Single phase 220VAC±5%, 50Hz/60Hz |

|

Digital input signal |

Level signal,low level is actual,5mA |

|

Digital Output Signal |

Max. load current I≤50mA |

|

DC Output Power 1 |

5V/100mA,10V/50mA,24V/30mA |

|

DC Output power 2 |

10V/10mA, |

|

Reply Output Signal |

Contact rating:250VAC/3A,30VDC/1A |

|

Analog input Signal |

10V/10bit |

|

Analog Output Signal |

10V/10bit |

|

Ambient Temperature |

-10~+50℃ |

|

Humidity |

20~90%RH,No condensation of water droplets |

|

Vibration |

< 0.5G |

|

Outline Dimension(W*H*T) |

96mm*96mm*110mm |

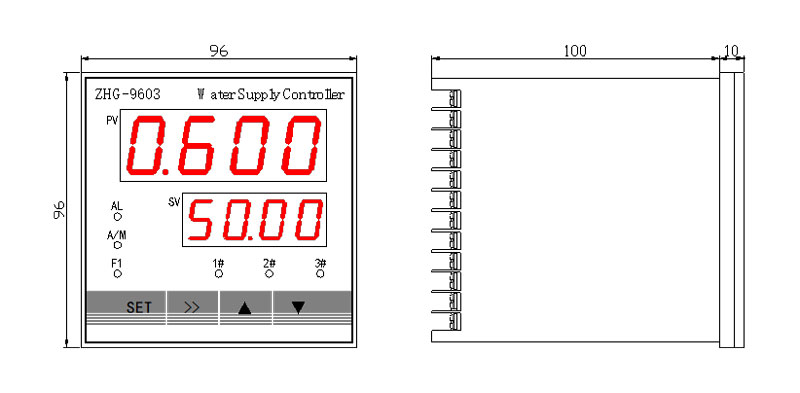

Controller Outline Dimension

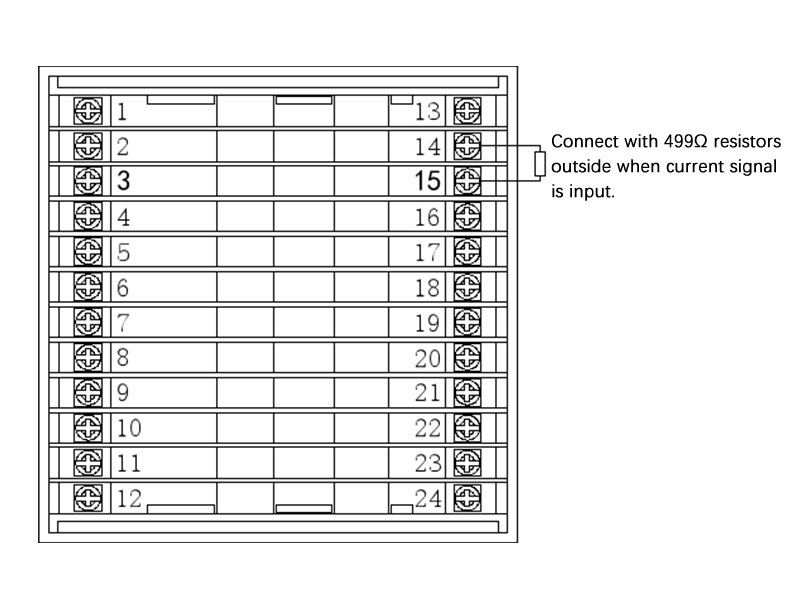

Controller circuit terminal

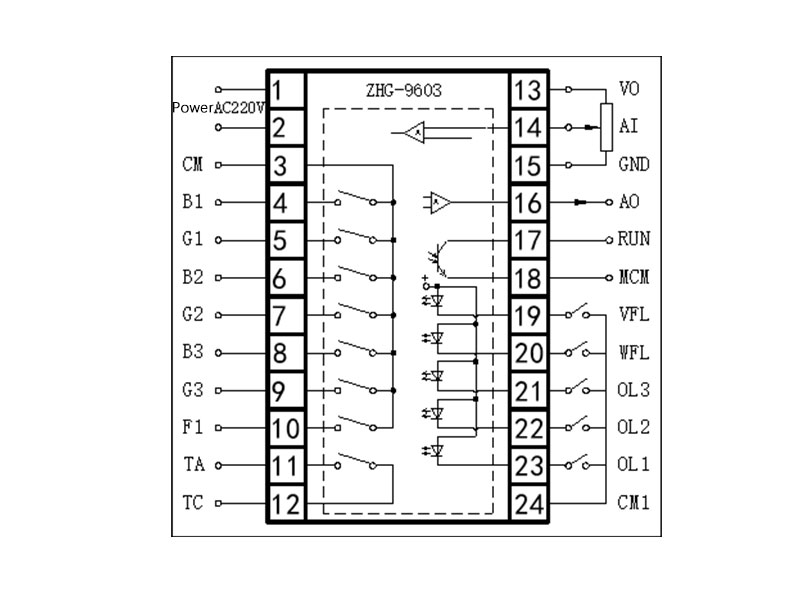

Controller Wiring Schematic Diagram

For the setting method of the controller, Please see page 6 and 7 of the manual. The working mode is shown in the following parameter settings:

For example:Meter range is 1.6Mpa, users request is set to 1Mpa constant pressure, the controller will start if pressure <0.6Mpa.

1. One inverter run with one motor,The parameters are set as follows:

The setting pressure: F000=1.00

over-pressure alarm pressure: F004=1.30

Meter range: F012=1.60

Sleep frequency: F029=30.0

Wake-up pressure width: F031=0.40 <(F000-F031=0.60this pressure wake up,it will start the inverter.

Pump 2 property: F042=0

Pump 3 property: F043=0

2. One Inverter run with two motors . parameter are set as below:

The setting pressure: F000=1.00

Over-pressure alarm pressure: F004=1.30

Meter range: F012=1.60

Increase pump pressure threshold width: F022=0.05 <(F000-F022=0.95Mpa)the pressure wake up, and frequency up to 50HZ, to add pump after deferring

Reduce pump frequency: F025=35.0

Sleep frequency: F029=30.0

Wake-up pressure width: F031=0.40 <(F000-F031=0.60)the pressure wake up .start the inverter .

Pump 3 property: F042=0

3. One Inverter run with three motors . parameter are set as below:

The setting pressure: F000=1.00

Over-pressure alarm pressure: F004=1.30

Meter range: F012=1.60

Increasing pump pressure threshold width: F022=0.05 <(F000-F022=0.95Mpa) the pressure wake up, and frequency up to 50HZ, to add pump after deferring.

Reduce pump frequency: F025=35.0

Sleep frequency: F029=30.0

Wake-up pressure width: F031=0.40 <(F000-F031=0.60)less than awaking .Run VFD.

Small Pump setting as below:

With auxiliary pump:

Small pump starting pressure width: F034=0.08 equal (F000-F034=0.92), sleep status,small pump will start if less than the pressure .

Small pump stop pressure width: F035=0.05 equal(F000+F035=1.05),at sleep status,small pump will stop if bigger than the pressure.

Without auxiliary pump:

F033=0;(also can remain and do not change )

See page 4-5 for terminal wiring diagram,Feel free to contact for control circuit wiring diagram from our company.

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

Release Date:2025-10-15> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

Release Date:2025-10-09> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

Release Date:2025-09-25> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...

Release Date:2025-09-18