ZVF600-G series IP54 general inverter is the company's own research and development of high degree protection pump inverter, the shell is dustproof and splash water, can be installed different brand water pump motor junction box. Adapt to a variety of sensor signals, simple operation, high reliability, low noise, can be individually controlled a pump and can also be more on-line operation.

◆ high protection IP54 , all-round anti-corrosion anti-splash water

◆ High performance V / F and vector control

◆ Professional heat-resistant design, small power, without fan can be more reliable

◆ Directly installed on the motor, no need for the cabinet, simple and convenient to operate .

◆The function and software is same as ZVF300H series. can be used for water supply system and general purpose .

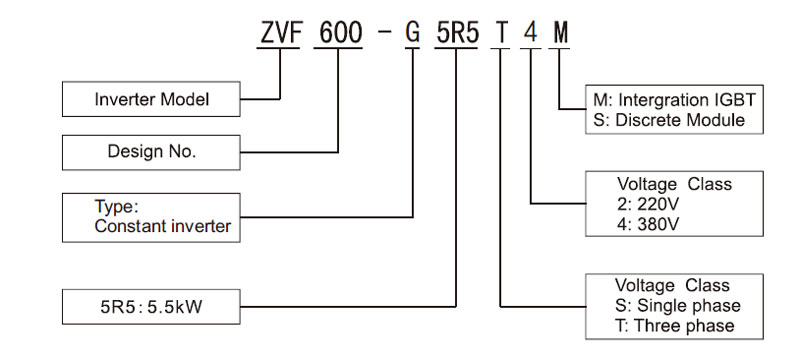

Demonstration of the Model

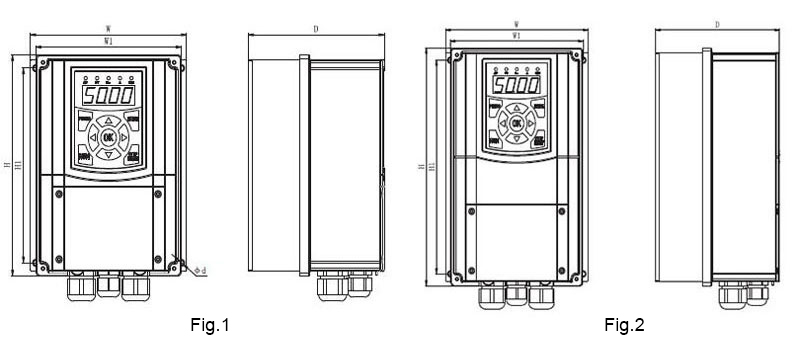

Inverter Outline& Mounting Dimension (Unit:mm)

ZVF600 IP54 Inverter Model Selection

|

Inverter Model |

Voltage (V) |

Power (kW) |

Current (A) |

Dimension (mm) |

Figure |

|||||

|

H |

H1 |

W |

W1 |

D |

d |

|||||

|

ZVF600-G0R7S2M |

220V |

0.75 |

4.5 |

193 |

170 |

150 |

140 |

131 |

4.5 |

Fig.1 |

|

ZVF600-G1R5S2M |

1.5 |

7.0 |

||||||||

|

ZVF600-G2R2S2M |

2.2 |

10 |

||||||||

|

ZVF600-G3R7S2M |

3.7 |

16 |

228 |

205 |

150 |

140 |

131 |

4.5 |

Fig.2 |

|

|

ZVF600-G0R7T4M |

380V |

0.75 |

2.5 |

193 |

170 |

150 |

140 |

131 |

4.5 |

Fig.1 |

|

ZVF600-G1R5T4M |

1.5 |

3.7 |

||||||||

|

ZVF600-G2R2T4M |

2.2 |

5.0 |

||||||||

|

ZVF600-G3R0T4M |

3 |

6.8 |

||||||||

|

ZVF600-G4R0T4M |

4 |

9.0 |

228 |

205 |

150 |

140 |

131 |

4.5 |

Fig.2 |

|

|

ZVF600-G5R5T4M |

5.5 |

13 |

||||||||

|

ZVF600-G7R5T4M |

7.5 |

17 |

||||||||

|

Item |

Item description |

|

|

Input |

Rated voltage& Frequency |

Single /Three phase 220VAC . Three phase 380V.50Hz/60Hz |

|

Allowable Voltage range |

Voltage fluctuate range:-20%~+20% Voltage unbalance rate:<3%;Frequency fluctuation:≤5% |

|

|

Output |

Rated voltage |

three phase 0~ input AC voltage |

|

Frequency |

0.00~600.00Hz |

|

|

Basic Function |

Frequency accuracy |

Digital setting::Max. Frequency×±0.01% Analog setting:Max. Frequency×±0.2% |

|

Frequency resolution |

Digital setting :0.01HZ; Analog setting :Max. Frequency x0.1%. |

|

|

Starting frequency |

0.00~50.00Hz |

|

|

Acceleration/deceleration time |

0.1~3600 can be set in sequence . |

|

|

Carrier frequency |

1.0~15.0KHz |

|

|

V/F curve |

1:linear curve;2:quadratic;3:user defined V/F curve |

|

|

Automatic energy-saving operation |

Auto optimize V/F curve according to the load changes to realize the energy saving operation . |

|

|

Built-in PID |

This can form a convenient closed-loop control system (CLCS)and is applicable to pressure control, flow control and other process control . |

|

|

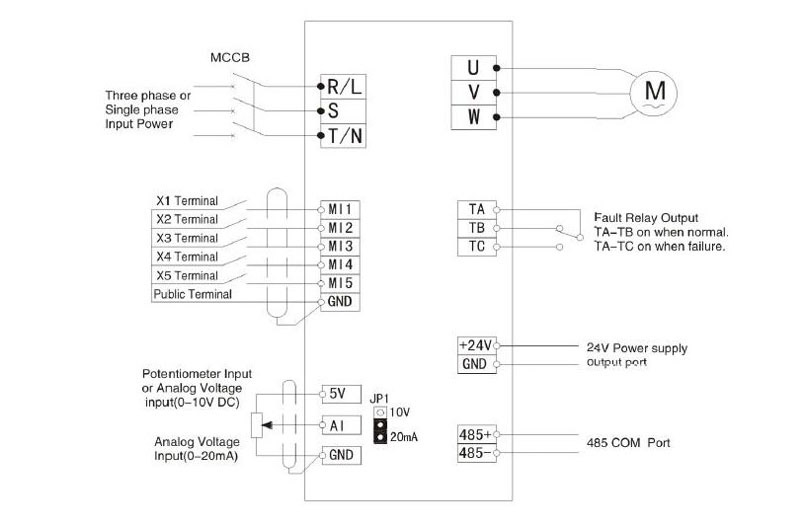

Operating command |

Operation panel control ,external terminal control and COM control |

|

|

Frequency setting |

Keypad potentiometer setting , operation panel▲▼setting,. analog voltage signal or external potentiometer setting , analog current signal setting .terminal combination setting ,485 COM setting and so on. |

|

|

Input Signal |

Forward/Reverse signal、multi-speed signal 、 fault signal 、 reset signal etc |

|

|

Output Signal |

Programmable relay |

|

|

Other Function |

Over voltage alarm 、Rotation speed tracking、 Momentary power loss restart 、Frequency upper/lower limiting、 Acceleration/ Deceleration mode can be adjusted 、Multi-speed/ program running、Fault auto reset、RS485 serial communication . |

|

|

Protection Function |

Input phase loss protection、 Over current protection 、Overload protection、 Over voltage protection 、Under voltage protection、 Over heat protection ect. |

|

|

LED Display |

Can display the real time running status of the inverter , monitor parameter .function parameter and fault code and other information of the inverter. |

|

|

Ambient |

Place to be used |

Indoor location free from direct exposure to sun light, high humidity or dew condensation, high levels of dust, corrosive gas, explosive gas, inflammable gas, oil mist, salt and etc |

|

Altitude |

Below 1000 M |

|

|

Ambient Temperature |

-10 ℃ to +45 ℃ (Bare Machine: -10 ℃ to+50 ℃) |

|

|

Humidity |

20%-90% RH without dew condensation |

|

|

Vibration |

<0.5G |

|

|

Storage temperature |

-20~+60°C |

|

Related Products

News Center

> When Should You Use a Soft Starter for Your Electrical Systems?

Many facility managers and electrical equipment buyers face confusion: they know motors need proper starting support, but they're not sure when to add a specific dev...

Release Date:2025-10-15> Which Factors Should You Consider When Choosing a Frequency Inverter for Industrial Use?

Many industrial buyers feel unsure when picking a Frequency Inverter for their operations. With different models and technical terms around, it’s hard to know where ...

Release Date:2025-10-09> What Situations Call for a Soft Starter?

Motors are core components in many industrial setups, but their startup process often brings hidden risks. Sudden power surges or mechanical shocks can damage equipm...

Release Date:2025-09-25> How to Tell If Your Frequency Inverter Needs to Be Replaced?

Many users of motor control equipment know how to use a frequency inverter daily but struggle to tell when it needs replacement. Waiting for total failure causes une...

Release Date:2025-09-18